PREMIUM Efficiency Three Phase Electric Motor 400v AC TEC IE3

This listing is for a Premium Efficiency Three Phase Electric Motor with a classification of IE3. We also sell standard and high efficiency motors in separate listings. Our aim is to make this as simple as possible for you, if you don't know exactly what you need then please don't worry as we're here to help (and you're not alone). If you're replacing a current motor then we have a guide below which will help you identify your motor, but the safest and easiest way to get exactly what you need is to send us a photo of the name/data, or new enquiry, to..

Powerline Electric Motors of Banbury (Oxford) offer a comprehensive stock of Electric Motors; 3 phase, single phase, high, premium or standard efficiency, aluminum or cast iron, compact or standard frames. We work with customers and industries such as FMCG, Formula 1, Farming, Healthcare, Construction, Chemical, Aerospace and Utilities. All of our work is delivered to industry-leading standards as set out by the Association of Electrical and Mechanical Trades (AEMT). The association represents companies who manufacture, distribute, install, service, maintain and repair industrial machinery technology such as electric motors, drives, pumps, fans, gearboxes, generators, transformers, switchgear and ancillary equipment. As members, Powerline agrees to uphold the association's code of practise and work to a set of principles, qualities, and standards as outlined on the association's website. As members, we also support the association in its activities and initiatives. Below is a guide to help you decode your electric motor name data plate. Whether you are looking to replace or repair a motor, the most relevant information should be recorded on the motor's nameplate. To help understand the information on motor nameplates, below is a guide to help you understand what the key elements mean. Electric Motor Name Data Plate. This indicates some of the motor's key dimensions and will usually be at the top of the nameplate as it is an important metric.Frame sizes conform to a standard that defines a motor's dimensions and outputs. The frame size is the height of the shaft's centre from the base of the motor's foot. A 315 frame, as in this example, will have a dimension from foot to shaft of 315mm. The number will be followed by a letter, S is for a short foot, M is for a medium foot, and L is for a large foot.

This letter defines the dimension between the mounting holes on the front and back feet. The motor's power may be written in kilowatts (kW) or horsepower (hp). It will be written in kW on most motors, but older motors may be rated in hp. Where there is more than one voltage figure listed, the delta (symbol) connection is the low voltage connection, while the star (symbol) configuration is for a high-voltage connection. The wiring diagram for both delta and star configurations will often also be added to the nameplate.This is the maximum speed of the motor in revolutions per minute without a load present, and this information can also tell you how many poles your motor has. A motor requires a minimum of two poles per phase and a 2-pole motor rotates fully for each polarity change. Therefore, at 50Hz, the theoretical maximum speed a 3-phase motor can run at is 3,000rpm. So, a motor labelled as having a speed around 3,000rpm will be a 2-pole motor. The reality is slightly slower in induction motors due to losses from factors such as drag and windage - referred to as slip.

As rpm halves, then the number of poles will have to double. Therefore, a motor rated at around 1,500rpm (1,490rpm in our example) will be a 4-pole motor. Efficiency is a significant factor where motors are concerned and is typically indicated by an IE number. IE1 is known as standard efficiency, IE2 is high efficiency, IE3 is premium efficiency, and IE4 is super premium.

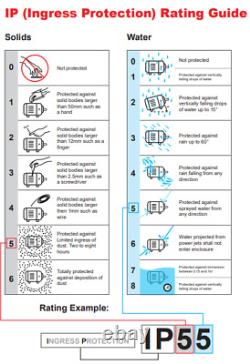

There is a significant difference in efficiency between IE1 and IE4. That represents halving the losses, which can account for a significant cost saving. IP stands for ingress protection - a device's ability to stop foreign material from entering and interfering with its operation. The first of two digits after the IP represents the level of protection from solid matter and the second liquids. The first can range from 0 - no protection - to 6 - total protection from dust.

The second goes from 0 - no protection from liquids - to 9 - resisting high pressure water jets. Your motors may also include other information, such as the Ex symbol, applied to motors designed for use in potentially explosive environments. Some manufacturers will include the bearing sizes on their nameplates (7). The nameplate may also show what insulation class the motor has been wound to (9).

The repair standard for rotating machines states that a motor can be repaired to the same or a better insulation class, so this is important information for a repair provider to have. The duty cycle may also be on the nameplate. In our example, S1 (10) stands for continuous duty and indicates that this motor has been designed to run 24/7, 365 days a year without issues - subject to scheduled maintenance. Ten duty cycle classifications cover examples such as short term use, intermittent duty and variable load. FAQ's: Which bearings are fitted in our motors?

Aluminum are fitted with either 2RS or ZZ NSK bearings throughout the range. Cast iron are fitted with standard re-greaseable bearings which have no reference after, just the bearing number E.

G 6309 C3 instead of 6309 2RS C3. What is a 7 series or Angular contact bearing? A 7 series bearing is also known as an angular contact bearing or a thrust bearing.

The code for this would be 7316 instead of the standard 6316. They are bearings that have a higher weight carrying capability in comparison to a normal ball or roller bearing and we recommend that these are fitted 280 frame and above on motors that are vertically shaft down mounted (V1) on the drive end, to help withstand the weight of the motor's rotor. What is a NU bearing? A NU or NJ bearing is a roller bearing. NU bearings are standard on our 4,6 and 8 pole motors in 315 and 355 frame.Roller bearings are available in other sizes and are always re-greaseable so need to be fitted to a motor that has re-greasing tubes as standard. What is an encoder and what does it do? An encoder is a feedback devise that is fitted to the motor shaft. The idea of this is that the encoder senses the speed of the motor shaft and feeds this back to whatever software is installed on the other end of the cables. They are normally used when the exact speed of a motor is critical.

What is an insulated bearing? An insulated bearing is a bearing that stops excess eddy currents from inverters travelling into the stator and potentially making the motor shaft live. The insulated bearing would normally be fitted on the none drive end of the motor and generally we would only fit one. We fit these on request but recommend that any motor 250 frame and above have these fitted when the motor is supplied by an inverter.

What is a 2RS bearing in comparison to a ZZ or 2Z bearing? 2RS means that the bearing is sealed for life with 2 rubber shields. ZZ or 2Z means that the bearing is sealed for life with 2 metal shields. What is HTL and TTL on encoders? HTL and TTL are the different incremental encoder signal types. What is the benefit of epoxy paint? Epoxy paint is a thicker, more resistant paint finish to the standard that is sprayed on our motors. Epoxy paint is normally used in saline atmospheres to stop salt in the air eroding the motors. It can also be used in areas where there is a risk of chemical erosion. C3 is the clearance tolerance between the outer race of the bearing and the internal of the bearing housing. All of our motor bearings are C3 tolerance although other tolerances are available upon request. What is the difference between 1024PPR encoders and 2048PPR encoders? PPR stands for pulses per revolution so a 1024 pulses 1024 times per revolution and a 2048PPR 2048 times. The software controlling the encoder will depend which option the customer requires. What does an anti-condensation heater do? An anti-condensation heater is used in motors that will work in cold environments, to stop the motor from condensating when it is turned off. The heater enables the winding to cool down slowly rather than going from very hot to very cold, meaning that condensation risk is eliminated. What is the normal ambient temperature for motors? -20°C to +40°C is the design ambient for all of our motor ranges.For any requirements outside of this range, please contact the sales team who will be able to advise the best possible solution. Tropicalisation is a process where an anti-tracking varnish is sprayed onto the windings to prevent winding ingress and fungi growth when the motor is installed in tropical conditions. What are the 2 blue cables in the connection block on 3 phase motors? They are PTC thermistors that give a resistance value to show whether the motor winding is running within its temperature limits or overtemperature.

They need to be connected to a PTC thermistor relay and the thermistors themselves do not disconnect the supply, they are only for measurement. At normal temperature, they will output 250 ohms and when the rated temperature has been exceeded, they will output over 2000 ohms.

My single phase motor is running hot, why is this? Single phase motors generally operate with a case temperature of around 60-70°C. For anything over this it could be either underload or overload. Underloading is a problem on single phase motors as the motor will always pull close to full load current and any excess energy is dissipated as heat causing excessive case temperatures.

TEC recommend that the closest possible single phase motor is selected for the application requirements. Another solution to this for motors 1.5kw or smaller is to use a 1ph-3ph inverter and a 3ph motor, for more details please contact the sales team. When is forced ventilation required and what is the benefit? A force vent fan is a fan that should be supplied with a constant 230/1/50 or 400/3/50 supply depending on the type fitted. They are normally fitted to motors that are run on an inverter below 25hz or above 75hz.The advantage is that the fan is constant running so even when the motor is run slowly, it can still be cooled by the force vent fan. This item is in the category "Business, Office & Industrial\Industrial Automation & Motion Controls\Electric Motors\General Purpose Motors". The seller is "powerline_motors_ltd" and is located in this country: GB. This item can be shipped to United Kingdom.

- Mounting Method: Foot & Face Mounted (B34 bolt into)

- Motor Speed (RPM / Poles): 2 Pole / approx. 3000 rpm

- Motor Power (Kilowatts): 0.75 Kw

- Brand: TEC

- EFFIENCY RATING: IE3

- Current Type: AC

- Rated Load (HP): VARIOUS

- Construction: Aluminium

- Nominal Rated Input Voltage: 400 V, 3 Phase

- AC Phase: Three Phase