Fluke 1732 Three Phase Electrical Energy Power Logger Analyzer

The Following Items Are Included. Fluke 1732 Three-Phase Electrical Energy Power Logger Analyzer (BC# 41481). (3) Fluke iFlex 300-24 Cables. (2) Fluke Flexible Test Leads.

Fluek 1732 Quick Reference Guide. This Item Has A Current Calibration! Fluke 1732 Three-Phase Electrical Energy Power Logger Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits.Includes Carrying Case & Accessories As Listed Above! Fluke 1732 Three Phase Electrical Energy Logger.

Energy logging is now within your reachdiscover where youre wasting energy, optimize your facilitys energy use and reduce your bill. The new Fluke 1732 and 1734 Three-Phase Electrical Energy loggers introduce a new simplicity to discovering sources of electrical energy waste. Discover when and where energy in your facility is being consumed; from the service entrance to individual circuits. Access and share data remotely with your team via the Fluke Connect® app so you can maintain safer working distances and make critical decisions in real-time, reducing the need for protective equipment, site visits and check-ins. Profiling energy usage across your facility helps you identify opportunities for energy savings, and provides you with the data you need to act on them.

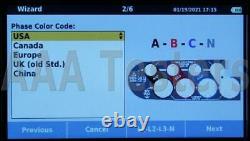

The new Energy Analyze software package allows you to compare multiple data points over time to build a complete picture of energy usage, which is the first step to reduce the cost of your energy bill. Measure all three phases: With included 3 flexible current probes. Comprehensive logging: More than 20 separate logging sessions can be stored on the instruments. In fact, all measured values are automatically logged so you never loose measurement trends. They can even be reviewed during logging sessions and before downloading for real-time analysis.Optimized user interface: Quick, guided, graphical setup ensures youre capturing the right data every time, and the intelligent verification function indicates correct connections have been made, reducing user uncertainty. Bright, color touch screen: Perform convenient in-the-field analysis and data checks with full graphical display. Optimized user interface: Capture the right data every time with quick, guided, graphical setup and reduce uncertainty about your connections with the intelligent verification function.

Complete in-the-field setup through the front panel or Fluke Connect: No need to return to the workshop for download and setup or to take a computer to the electrical panel. Fully integrated logging: Connect other Fluke Connect devices to the Fluke 1734 to simultaneously log up to two other measurement parameters, virtually any parameter available on a Fluke Connect wireless digital multimeter or module. Energy Analyze Plus application software: Download and analyze every detail of energy consumption with our automated reporting. Load studies: Discover how much energy individual pieces of equipment are consuming when they are operating at minimum and maximum capacity.Check capacity of circuits prior to adding additional loads (various standards exist for this process; in the US the NEC 220- 87 is the recommended standard). Load studies can also identify situations where you may be exceeding the allowable load on the circuit or when an agreed peak demand applies from the utility. For convenience, some load studies simply measure current which makes installation of the measuring equipment quick and easy. It is often recommended that load surveys be performed for 30 days so that all typical load conditions are encountered during the test.

Energy assessments: quantify energy consumption before, and after improvements, to justify energy saving devices. Energy surveys: Users often ask where measurements should be taken for an energy survey.The answer is multiple points within the facility. Start at the main service feeders; compare the power and energy measured here with the readings from the utility meter to ensure youre receiving the correct charges. Measuring at many points will allow a full picture of energy usage across the facility to be developed. The next question users typically have is how long an energy survey should last. This of course depends on the facility, but it is recommended that you measure for a period that matches a typical facility activity period.

If the facility operates over a five day work week with down time on the weekend, a seven day survey will most likely capture typical conditions. If the facility operates Applications at a constant level for 24 hours a day, 365 days a year, a single day could be reasonably representative as long as you avoid a period where there may be planned maintenance. To capture a full picture of the facilities energy usage it is not necessarily required to have measurements made simultaneously at every consumption point in the facility. To get a comprehensive picture, spot measurements can be made and then compared on a sliding time timescale. Typically there will be some correlation between these profiles.Logging related analog measurements: When conducting energy studies, it is useful to log related analog measurements such as temperature, voltage, current or pressure. These variables provide a better overall picture of operating conditions and allow you to correlate asset performance data with energy consumption.

Correlating these variables provides more of the data you need to make cost saving performance adjustments. With the Fluke 1734, up to two Fluke Connect wireless modules can be used to capture these measurements, and the values will be automatically logged along with power and energy readings. Power and energy logging: When a piece of equipment is operated it instantaneously consumes a specific amount of power in watts (W) or kilowatts (kW).This power is accumulated over the operating time and expressed as energy consumed in kilowatt hours (kWh). Energy is what your electric utility charges for; there will be a standard charge from the utility per kilowatt hour. Utilities may have other additional charges, such as peak demand, which is the maximum power demand over a defined period of time, often 15 or 30 minutes. There may also be power factor charges, which are based on the effects of the inductive or capacitive loads in the facility. Optimizing peak demand and power factor often results in lower monthly electricity bills.

Simplified load studies: For situations where its either difficult or impractical to make a voltage connection the simple load study feature allows users to perform a simplified load study by measuring current only. The user can enter the nominal expected voltage to create a simulated power study. For accurate power and energy studies it is required to monitor both voltage and current but this simplified method is useful in certain circumstances. The four current probes are connected separately; the instrument automatically detects and scales the probes. The thin current probes are designed to easily get through tight conductor spacing and are easily set to 150 or 1500 A for high accuracy in nearly any application.

An innovative tangle-free flat voltage lead makes connection simple and reliable and the instruments intelligent Verify Connection feature automatically checks to make sure the instrument is connected correctly and can digitally correct common connection issues without having to disconnect measurement leads. ± (0.2 % + 0.01 %).

42.5 Hz to 69 Hz. ± (0.2 % + 0.02 %). ± (1 % + 0.1 %).

± (5 % + 0.2 %). 100 V to 500 V using safety plug input when powering from the measurement circuit.100 V to 240 V using standard power cord (IEC 60320 C7). 15 VA when powered using IEC 60320 input.

68.2 % (in accordance with energy efficiency regulations). 50/60 Hz ± 15 %.

Li-ion 3.7 V, 9.25 Wh, customer-replaceable. Four hours in standard operating mode, up to 5.5 hours in power saving mode. 10.24 kHz at 50/60 Hz, synchronized to mains frequency.50/60 Hz (42.5 to 69 Hz). 1-, 1- IT, split phase, 3- delta, 3- wye, 3- wye IT, 3- wye balanced, 3- Aron/Blondel (2-element delta), 3- delta open leg, currents only (load studies). Internal flash memory (not user replaceable).

Typical 10 logging sessions of 8 weeks with 1-minute intervals and 500 events. Voltage, current, aux, frequency, THD V, THD A, power, power factor, fundamental power, DPF, energy. User selectable: 1 sec, 5 sec, 10 sec, 30 sec, 1 min, 5 min, 10 min, 15 min, 30 min. Voltage, Current: Full cycle RMS updated every half cycle Aux, Power: 200ms.Demand Interval (Energy Meter Mode). Energy (Wh, varh, VAh), PF, maximum demand, cost of energy. User selectable: 5 min, 10 min, 15 min, 20 min, 30 min, off. File transfer via USB flash drive, firmware updates, max.

File transfer and remote control via direct connection or WiFi infrastructure. Read auxiliary measurement data from Fluke Connect® 3000 series modules (requires 1734, or 1732 upgrade option). Data download device to PC.

4 (3 phases and neutral). 1000 Vrms, CF 1.7. 42.5 Hz - 3.5 kHz. 1000 V CAT III/600 V CAT IV. 3, mode selected automatically for attached sensor.

Clamp input: 500 mVrms/50 mVrms; CF 2.8. 150 mVrms/15 mVrms at 50 Hz, 180 mVrms/18 mVrms at 60 Hz; CF 4; all at nominal probe range. 1 A to 150 A/10 A to 1500 A with thin flexible current probe i17XX-flex1500 12.

3 A to 300 A/30 A to 3000 A with thin flexible current probe i17XX-flex3000 24. 6 A to 600 A/60 A to 6000 A with thin flexible current probe i17XX-flex6000 36. 40 mA to 4 A/0.4 A to 40 A with 40 A clamp i40s-EL. 0 to ± 10 V dc, 1 reading/s. Format: mx + b (gain and offset) user configurable.

User configurable (7 characters, for example, °C, psi, or m/s). 10 °C to +50 °C (14 °F to 122 °F). 20 °C to +60 °C (4 °F to 140 °F), with battery: -20 °C to +50 °C (4 °F to 122 °F).

10 °C to 30 °C (50 °F to 86 °F) max. 30 °C to 40 °C (86 °F to 104 °F) max. 40 °C to 50 °C (104 °F to 122 °F) max. 2000 m (up to 4000 m derate to 1000 V CAT II/600 V CAT III/300 V CAT IV).

IP50 in accordance with EN60529. MIL-T-28800E, Type 3, Class III, Style B. IEC Mains Input: Overvoltage Category II, Pollution Degree 2.Voltage Terminals: Overvoltage Category IV, Pollution Degree 2. IEC 61010-2-031: CAT IV 600 V/CAT III 1000 V. EN 61326-1: Industrial CISPR 11: Group 1, Class A. Korea (KCC): Class A Equipment (industrial broadcasting and communication equipment).

USA (FCC): 47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103. 0.1 x accuracy specification/°C. 4.3-inch active matrix TFT, 480 pixels x 272 pixels, resistive touch panel. Instrument: 19.8 cm x 16.7 cm x 5.5 cm (7.8 in x 6.6 in x 2.2 in).

Power supply: 13.0 cm x 13.0 cm x 4.5 cm (5.1 in x 5.1 in x 1.8 in). Instrument with power supply attached: 19.8 cm x 16.7 cm x 9 cm (7.8 in x 6.6 in x 3.5 in). Instrument: 1.1 kg (2.5 lb). Power supply: 400 g (0.9 lb). Please check our Huge Inventory with savings of up to 80% off of retail on Cat5/5e/6 LAN Cable Certifiers and Fiber Optic OTDR's, Fusion Splicers, CATV Meters, Fiber Optic Kits, Sources, Meters, Tools, Network Analyzers and much more.

Here is a Link to our. Please don't hesitate to. For a Quote on Something you don't see in our inventory, sometimes we have items that may have not been listed or processed yet. Test Equipment Store Offers a wide range of Refurbished Telecom/ Datacom Tools and Test Measurement Equipment. Which includes Fiber Optic Test and Splicing tools, Fusion Splicers, OTDRs, Copper and Fiber Cable Certifiers, CATV Test Equipment, Cable and Antenna Analyzers, Network Analyzers and much more!We carry a large inventory of quality refurbished and used test equipment from all the major manufacturers. If you are looking for multiple quantities or if we don't have a listing for a particular item that you are looking for.

(Certain orders may take longer for processing due to comprehensive final service inspections). The item "Fluke 1732 Three Phase Electrical Energy Power Logger Analyzer" is in sale since Thursday, January 14, 2021.

This item is in the category "Business & Industrial\Test, Measurement & Inspection\Analyzers & Data Acquisition\Power Quality Analyzers". The seller is "test_equipment_company_store" and is located in Toledo, Ohio. This item can be shipped worldwide.

- Brand: Fluke

- MPN: 1732